We are dedicated to R&D to grow as a global innovative company.

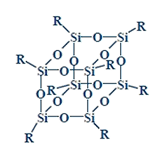

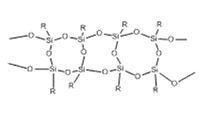

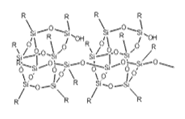

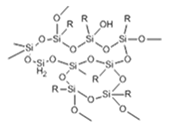

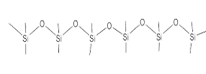

| Content | SSQ (POSS) | Ladder Structure | Partially Cage-like | Random network | Linear type |

|---|---|---|---|---|---|

| Structure |  |  |  |  |  |

| Application | High thermal | Photo sensitivity High thermal | Photo sensitivity Middle thermal | Hard coating Negative curing | Potting compound Encapsulation Silicone Oil |

| Advantage | High thermal stability Best physical performance | High thermal stability | Easy to make functional | High X-linking density Low cost High WVTR performance | Solvent-less compound High stress resistance |

| Drawback | High cost Impossible to define | Low compatibility Low crack resistance | Low density Low WVTR performance | Hard to structure control Low repeatability | Low WVTR Low Thermal stability |

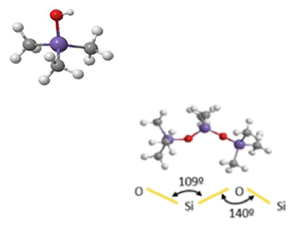

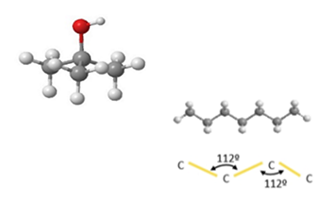

Comparison of Silicone-Based and Carbon-Based Polymers

| Siloxane Polymer | Carbon-Based Polymer | |

|---|---|---|

| Bonding Energy | Si-O: 1.54Å, ∆H = 798 kJ/mol Si-C: 1.87Å, ∆H = 435 kJ/mol | C-C: 1.54Å, ∆H = 368 kJ/mol C-O: 1.42Å, ∆H = 335 kJ/mol |

| Rotation Energy | Si-O: 0.8 kJ/mol | C-C: 15.1 kJ/mol C-O: 11.31 kJ/mol |

| Bonding Structure |  |  |

Characteristics of Silicone-Based Polymers

| Properties | Silicon Hybrid Polymer | Competitors | |||

|---|---|---|---|---|---|

| Silicon Resin | Epoxy Acrylate | Urethane Acrylate | Polyimide | ||

| Heat Resistance | High > 500°C | High > 600°C | Medium > ~250°C | Medium > ~250°C | High > 500°C |

| 내화학성 | High | High | High | Low | High |

| Weatherability | High | High | High | Low | Low |

| Insulating Properties | High | High | Fair | Fair | High |

| Hardness | High | Medium | Medium | Medium | Medium |

| Light Transmittance | High | Medium | Medium | Medium | Low-Medium |

| Coating Adhesion | High | Low | High | High | Low |

| Out Gas | Low | Low | High | High | High |